Ranger RL-8500 Combination Disc/Drum Brake Lathe with Bench & Standard Tooling

The revolutionary RL-8500 combination brake lathe uses independent DC servo motors to control the cross-feed and spindle feed drives, eliminating the need for complex mechanical gear boxes and transmissions typically found on mechanically-driven brake lathes.

The ruggedly built RL-8500 brake lathe is capable of faster, easier and more accurate rotor/flywheel and drum/flywheel resurfacing than any other brake lathe in its class. Infinitely adjustable feed rates allow you to easily modify cut speeds with the simple turn of a dial. Now you can reduce or increase the cut-time for the best finish results, whether you're speeding through an initial rough cut or a single-pass micro-finish. This complete lathe package includes the lathe, a sturdy bench and large tool storage backboards, so you can hang all your adapters within close reach.

One of the common problems that plague other brake lathes is the vibration and chatter transfer that directly affects the tool-tip and leaves an imperfect cut on the machined surface. The RL-8500 brake lathe by Ranger is specifically designed to address this issue by eliminating the need for gear-driven mechanical drives and variable-speed transmission devices.

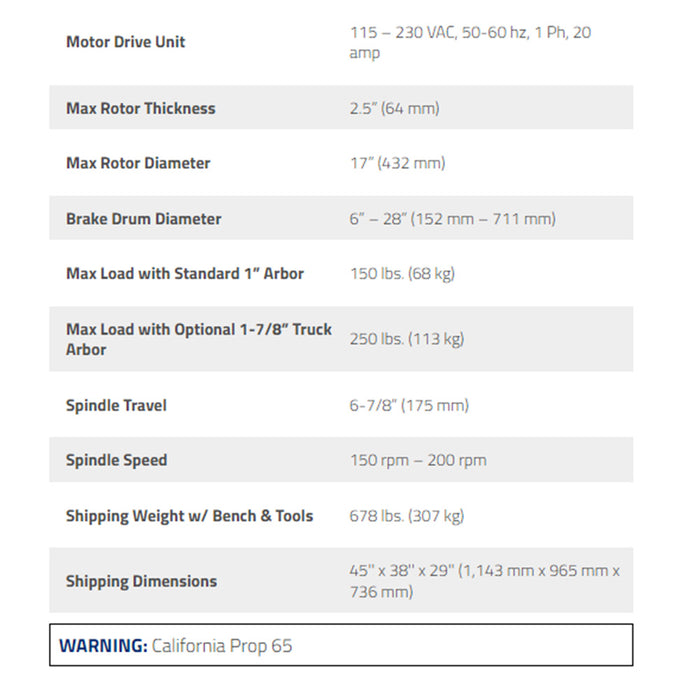

Specification:

- Precision electric DC servo motors designed to meet the demanding requirements of industrial motion control

- Quick-Change Adapter-Plus system with built-in springs eliminates the need for conventional bell clamps and cones

- Works with hubless drums, rotors (center hole sized 2-5/32" – 4") and composite rotors (center hole sized 4" – 6.25")

- The RL-8500 is equipped with features that help increase your service capability, like precision twin cutter tools and a quick drum-to-rotor changeover

- Infinitely variable spindle and cross feed speed settings allow for quick rough and precision finish cuts

- Simple ergonomic controls are designed for minimal operator movement

- Legendary control makes unit easy to learn and master

- The RL-8500 maintains accuracy year after year thanks to ruggedly constructed components like a hardened, precision ground spindle that resists grooving and makes boots a thing of the past

- Massive tapered spindle bearings offer superior weight support during rotation

- Exclusive "splash-lube" oil-feed system supplies a constant flow of oil to the bearings, making sure they provide years of trouble-free service

- Serpentine belts provide a faster, quieter operation, reducing chatter and vibration

- An independent cross feed motor eliminates the need for plastic or bronze shear gear that are expensive and time-consuming to replace

- A convenient top storage tray means your popular adapters and tools are kept within short reach

- Separate motors on the drum and rotor feed help maximize the main motor's efficiency

- Our deluxe standard adapter package includes a Quick-Change hubless adapter system that makes mounting rotors and drums quick and easy

- A variety of adapters let you machine all standard and composite rotors for foreign and domestic cars and light trucks

- A 450-lb. cast iron body and a solid work bench reduce transient vibrations, ensuring a smooth uninterrupted surface finish with each pass

- Easily change arbor speeds in seconds: choose 150 or 200 rpm, depending on the job

- Positive rake cutter tip angle provides a one-pass finish virtually every time, allowing you to complete your work faster than inferior multi-pass lathes

BENDPAK NUMBER #5150066

For warranty information, shipping, and FAQ, please visit: https://www.wurthtool.com/pages/bendpak