Ranger R80EX Tilt Back Tire Machine Dual Tower Assist - 34" ClampingmCapacity

The R80EX tire changer features a dual-assist, tilt-back tower design, so it's outfitted with the industry's best and most powerful tools. With the R80EX, you get the classic, rugged reliability Ranger is known for, plus dozens of standard features.

Looking to save time? An R80EX tire changer is a must-have machine for busy shops that don’t have a minute to waste. A multi-profile traveling drop-center tool, top bead assist rollers, dual lower bead lifting discs and a nylon non-marring wheel restraint device are important tire shop tools designed to dramatically reduce effort, increase safety and help minimize operator fatigue. A large 34” capacity turntable with adjustable hardened-steel RimGuard™ wheel clamps helps broaden the service range, so you can handle virtually any wheel that rolls in your shop. Explore this tire machine if your shop life demands a tool that will generously handle round-the-clock use and abuse.

Adjustable RimGuard™ wheel clampsRanger’s trademark wheel clamps feature internal and external multi-teeth jaws.

Variable clamp positioning makes wheel service simple, perfectly controlling the wheels when clamping them. Operators have the freedom to freely and precisely position clamps within the entire clamping range. There’s no need for the clamps to cycle the full range.

A geometric tabletop provides for easier bead lubrication and allows operators to make visual inspections of the lower bead during mounting and inflation procedures.

A bilateral, power-controlled bead loosener features single-lever control on the shovel handle. This ergonomic design eliminates traditional foot-pedal controls that often force technicians into unbalanced working stances when loosening beads. Designed for maximum comfort, efficiency, safety and ease of use, this valuable feature helps deliver additional power, speed and control, especially when servicing large or wide assemblies.

A multi-axis and adjustable bead loosener shovel blade helps accommodate a larger variety of tire and wheel combinations.

No more worrying about moisture contamination from corrosion due to air source condensation. The stainless-steel cylinder is completely resistant to chemical erosion, rust and other damaging effects of weather over time.

The oversized axle minimizes blade flex and improves durability.

The tire changer’s arm features a rugged box frame construction that increases strength and ensures years of dependable service and performance.

Industrial-grade, 45-micron pneumatic control valves feature die cast and machined bodies constructed from zinc and aluminum. High-performance polyurethane seals and self-lubricating, Teflon® piston guides provide increased service life and performance at the highest level possible within almost every imaginable working condition. Valve plungers feature muffled extrication ports that direct any dirt or contamination accumulated on the outside perimeter of the spool to be automatically blown away each time the valve goes into the release position.

R80EX features durable pneumatic internal control valves

A balanced flywheel helps the machine run smoothly, reduces vibration and helps minimize associated stress on other machinery components.

Durable forged steel (instead of cast iron) foot pedal levers will stand up to everyday use and abuse in high-volume tire centers. Snap action spring return means precise and controlled operation. Foot-pedal control valves feature multi-link rod connections for non-binding plunger movement and precise bilateral control.

All main-lead electrical terminals, auxiliary switches and motor enclosures are sealed for air-tight, dust-free and contamination-proof protection of terminal leads.

Ranger Next Generation™ tire changers feature high-pressure polyurethane pneumatic tubing with mirror-smooth seamless bore for exceptional flow rates, high abrasion resistance, high burst tolerance and maximum kink resistance.

Specially engineered drive belt features convex sidewalls to distribute wear evenly while providing proper belt support for improved service life. Both flex-bonded cords and flex-weave covers resist the effects of oil, heat, ozone, weather and aging.

A maintenance-free gearbox features a large oil and grease reservoir that helps provide efficient heat dissipation and improved lubrication for longer service life. Internal baffles and a constant-seating stress flange gasket ensure positive, leak-free venting. The rugged gearbox enclosure is precision-milled for precise alignment of horizontal and vertical bases and features precision helical gears that operate much more smoothly and quietly than typical spur gear transmissions. The rugged housing provides maximum strength for extreme durability under hard working conditions and greater precision under load during worm and gear alignment. High-strength, oversized worms and worm gears are straddle-mounted between heavy-duty tapered roller bearings, providing rugged dependability.

Improved electric motor features the best of proven technologies, including rugged copper rotor construction, high-quality bearings, thermal-cool epoxy insulation and durable rolled steel frames.

The R80EX has a new and improved 3 HP motor

Powerful left-side assist tower features a multi-profile traveling drop-center tool that holds stubborn sidewalls in the drop-center, a single lower bead lifting disc and a pneumatic non-marring wheel positioning and restraint device that simplifies external mounting procedures and helps restrain wheels during inflation. A tire iron slot built into the bead-lifting discs gives operators additional leverage for difficult tire handling. Upfront controls and a sensible ergonomic design provide ease of use and more efficient operation. Heavy-duty, tri-flange, cast-iron assist tower carriage features linear way bearings for years of maintenance-free operation.

Additionally, a right-side assist tower features dual power-drop top bead assist rollers that help hold top beads in place during removal and installation of tough sidewall tires. An additional bead-lifting disc and sidewall roller provide even more tire handling capability.

The tilt-back tower provides greater clearance and access for tire removal and inflation. Pneumatic-lock tool head stays positioned on the tower return for instant set up for like sets of tires and wheels.

Ranger’s cylinders are designed to reduce machine vibration and provide low friction and long life operation. Internal end-of-stroke cushions come standard and help provide support at the end of each full stroke to reduce wear on seals, wear band and piston rod.

The hardened alloy steel mount and demount head has a unique equi-dimensional shape that allows you to perform all changing functions with the tool head in the same position. The micro-smooth tool head surface glides tire beads effortlessly during mounting and demounting procedures to ensure costly tire damage is minimized.

Important wheel service accessories come standard, like a large soap bucket with brush and a multi-piece plastic wheel protector kit that includes turntable jaw covers, bead-breaker blade boots and specialized mount / demount head covers to help protect delicate wheels. We throw in a hardened steel tire iron and bead lever tool to assist during all tire mounting and demounting operations.

A rigid, 45 mm spring-assisted hexagonal vertical tool shaft, combined with a hardened-steel horizontal outrigger support arm, maintains perfect position of the mount-demount tool head during all tire service procedures to reduce the chance of expensive wheels getting damaged.

All moving parts feature maintenance-free linear guide bearings for easy adjustment of both vertical and horizontal wheel settings. The non-flex horizontal arm also features a hardened lower roller guide for smooth and controlled in-and-out movement.

Integrated rubber bump-stops ensure smooth return during tilt-back operations to help reduce shock loading and minimize wear on tower guides and moving parts.

A simple-to-use tire inflator features foot-pedal operation and inflation hose with a sure-grip clip-on valve chuck, enabling hands-free operation. Integrated air pressure dump valve enables you to lower tire pressure with a simple push of a button.

Ranger tire changers feature the renowned TurboBlast™ bead seating system that blasts a powerful air burst between the tire and rim to help seat stubborn beads fast. A durable, non-marring nylon discharge barrel features a contoured tab that locks securely on the edge of the rim for better control during air discharge between the tire and wheel. A welded-steel, eight-gallon surge tank is larger than competitive models for all the inflation power you need, when you need it.

Plenty of storage area for tools and accessories. Helps keep your shop tidy and operation-critical tools close at hand.

Stainless steel braided metal conduit protects hoses and wires from abrasion and wear.

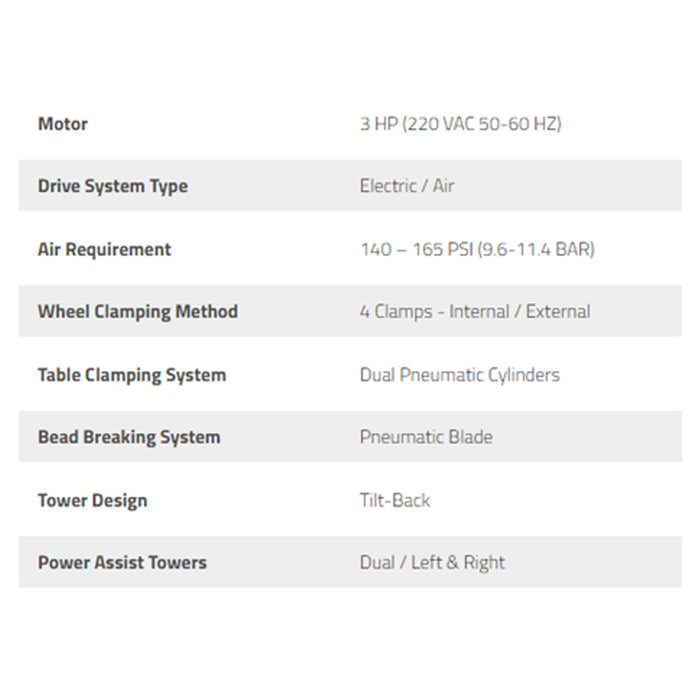

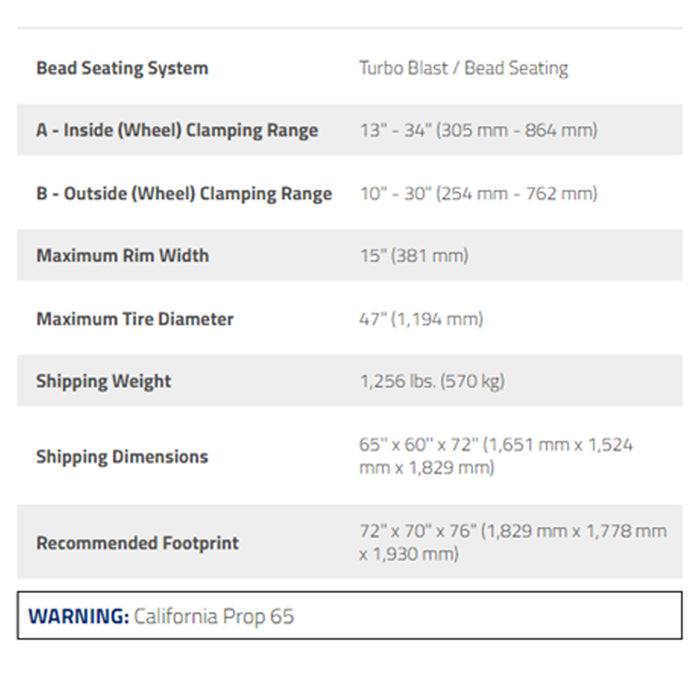

SPECS –

- Table Clamping System

- Dual Pneumatic Cylinders

- Wheel Clamping Method

- 4 Wheel Clamps - Internal / External

- Adjustable RimGuard™ Wheel Clamps

- Bead Loosener System

- Pneumatic Blade

- Bi-lateral Power-Controlled Bead Loosener

- Bead Loosener Control Single-Lever Control on Shovel Handle

- Power Assist Towers

- Dual / Left & Right

- Upper Bead Assist Roller

- Standard / Dual Power-Drop

- Traveling Drop-Center Hold Down Device

- Wheel Centering Tool / Inflation Restraint Device

- "Turbo-Blast" Bead Seating System

- Tool Tray / Bin Storage

- Inflation Gauge With Integrated Air Dump Valve

- Inflation Pressure Regulator/Limiter

- Water Filter / Oiler / Lubricator

- Air Regulator

- Tire Iron / Bead Lever Tool

- Large Soap / Lubricator Bucket

- Brush

- Tower Design Tilt-Back

BENDPAK NUMBER #5140139

For warranty information, shipping, and FAQ, please visit: https://www.wurthtool.com/pages/bendpak